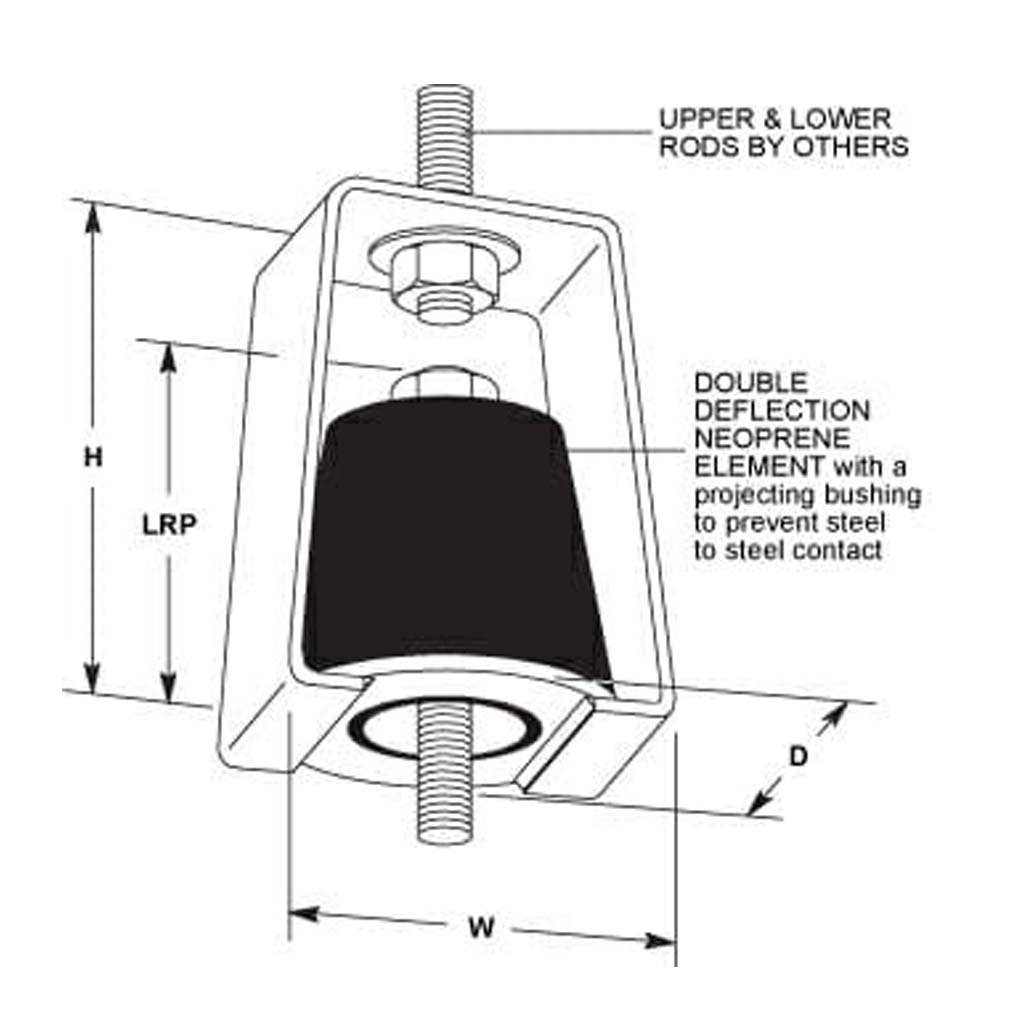

Rubber Hanger (Deflection : 3.5~13mm Anti Vibration Mounts Vibration And Seismic Controls

﷼17.98 – ﷼34.49

VAT is included in price

If you have not found the product you need. Feel free to contact us

Applications:

- For machine rooms, ventilators in air conditioning rooms and ducts

- For small fan and duct in line fan

- For structures suspended from the ceiling of, for example, studios and acoustical laboratories

- For ceiling mounded FCU

2 reviews for Rubber Hanger (Deflection : 3.5~13mm Anti Vibration Mounts Vibration And Seismic Controls

Description

Introduction:

Rubber hangers are made to isolate machinery and equipment from the vibrations generated during operation. They are a rubber element encased in metal brackets, providing flexibility and resilience to absorb shocks and vibrations. These mounts are commonly used in HVAC systems, industrial machinery, automotive applications, and even buildings to mitigate seismic activity’s effects.

Importance of Deflection in Anti-Vibration Mounts:

Deflection refers to the ability of rubber hangers to compress and rebound in response to vibrations. The deflection range, typically ranging from 3.5mm to 13mm, determines the effectiveness of the mount in absorbing vibrations. A higher deflection capacity allows the mount to handle greater shock loads and maintain stability even under extreme conditions.

Types:

standard Rubber Hangers:

These are the most commonly used rubber hangers and are suitable for a wide range of applications. They offer good vibration isolation and are cost-effective, making them ideal for general-purpose use.

Heavy-duty Rubber Hangers: Designed to withstand higher loads and provide enhanced vibration isolation, heavy-duty rubber hangers are used in applications where machinery or equipment generates significant vibrations or experiences heavy shocks. They offer greater durability and resilience, making them suitable for demanding industrial environments.

How Rubber Hangers Work:

Rubber hangers operate on the principle of converting kinetic energy from vibrations into heat, which is then dissipated through the rubber material. The rubber element acts as a cushion, absorbing the shock and preventing it from transmitting to the surrounding structures.

Benefits of Using Rubber Hangers:

Vibration Control: Rubber hangers effectively reduce the transmission of vibrations, ensuring smooth and quiet operation of machinery.

Noise Reduction: By dampening vibrations, rubber hangers help minimize noise levels in industrial environments, improving overall working conditions.

Seismic Protection: In earthquake-prone regions, rubber hangers play a crucial role in safeguarding buildings and equipment against damage caused by seismic activity.

Applications of Rubber Hangers:

Rubber hangers find widespread use in various industries, including:

HVAC Systems: Rubber hangers are widely used in heating, ventilation, and air conditioning (HVAC) systems to mount components such as ductwork, fans, and compressors. They help reduce vibrations and noise, ensuring the smooth and quiet operation of HVAC equipment.

Industrial Machinery: In industrial settings, rubber hangers are employed to isolate heavy machinery and equipment from vibrations generated during operation. They are used in manufacturing facilities, production lines, and processing plants to minimize the transmission of vibrations to the surrounding structures and machinery.

Automotive Manufacturing: Rubber hangers play a crucial role in the automotive industry, where they are used to mount exhaust systems, engines, and other components in vehicles. By absorbing vibrations and shocks, rubber hangers help improve vehicle performance, comfort, and longevity.

Aerospace: In the aerospace sector, rubber hangers are utilized to mount sensitive equipment and instrumentation in aircraft, satellites, and spacecraft. They help minimize vibrations and ensure the stability and reliability of critical aerospace systems during flight.

Construction: Rubber hangers find applications in construction projects, particularly in buildings and structures that require vibration and noise control. They are used to mount HVAC equipment, piping systems, and mechanical components to prevent vibrations from affecting the building occupants and surrounding structures.

Power Generation: Rubber hangers are employed in power generation facilities, including thermal power plants, hydroelectric dams, and wind farms, to support and isolate machinery such as turbines, generators, and pumps. By dampening vibrations, rubber hangers help maintain the integrity and efficiency of power generation equipment.

Installation Process of Rubber Hangers:

Installing rubber hangers requires careful positioning and alignment to optimize their effectiveness. Proper installation helps maximize vibration isolation and prolong the lifespan of the mounts.

Maintenance Tips for Rubber Hangers:

Regular inspection and maintenance are essential to ensure the continued performance of rubber hangers. This may include checking for signs of wear, tightening fasteners, and replacing worn-out mounts as needed.

Comparing Rubber Hangers with Other Mounting Solutions:

Rubber hangers offer several advantages over alternative mounting solutions, such as coil springs or elastomeric pads, including better vibration isolation, noise reduction, and seismic protection.

Innovations in Rubber Hanger Technology:

Ongoing research and development efforts continue to enhance the design and performance of rubber hangers, leading to innovative solutions for addressing specific vibration challenges.

Environmental Impact of Rubber Hangers:

Rubber hangers are generally considered environmentally friendly, as they are made from recyclable materials and contribute to energy savings by reducing machinery noise and vibrations.

Future Trends in Rubber Hanger Development:

The future of rubber hangers lies in advancing technologies that offer greater efficiency, durability, and sustainability, catering to evolving industry demands and environmental concerns.

Conclusion:

Rubber hangers play a vital role in controlling vibrations and ensuring the smooth operation of machinery and equipment across various industries. By understanding their significance, types, working principles, benefits, and applications, stakeholders can make informed decisions when selecting and utilizing rubber hangers for their specific needs.

FAQs:

Yes, rubber hangers are designed to withstand a wide range of environmental conditions, making them suitable for both indoor and outdoor use.

Absolutely, rubber hangers provide effective seismic protection by isolating the structure from ground motion during earthquakes.

Regular inspection for wear and tear, as well as ensuring proper alignment and tightness of fasteners, is essential for maintaining the performance of rubber hangers.

The lifespan of rubber hangers depends on various factors, including the operating conditions and frequency of vibrations, but with proper maintenance, they can last for many years.

Yes, rubber hangers are typically made from recyclable materials and can be repurposed at the end of their service life.

Related products

-

Pipe Insulation 1.8m * 9mm (made in Saudi Arabia)

5.00 out of 5﷼1.80 – ﷼210.00 -

G.I Nuts 10mm & 8mm, Threaded part 50mm

5.00 out of 5﷼10.35 – ﷼230.00 -

Delmon Duct Glue (81*10) 6 IBS (1.35 KG/L)

4.00 out of 5﷼194.00 -

G Clamp, 75mm-200mm. E20-3 – E20-8 Multipurpose Load Bearing Hanger

5.00 out of 5﷼0.75 – ﷼234.00 -

PVC Pipe Wrapping Tape Thickness: 0.2mm x 2 Inches PVC Black

5.00 out of 5﷼4.50 – ﷼210.00 -

Damper Quadrant Handle (1/2″ , 3/4″ , Butterfly)

4.50 out of 5﷼6.00 – ﷼15.00 -

Strapping seal, Packing seal, 12mm,16mm,24mm, 22-28 Gauge.

0 out of 5﷼11.00 – ﷼210.00 -

Uninsulated Flexible 4, 6, 8, 10, 12 Inches

5.00 out of 5﷼32.50 – ﷼4,312.50 -

Canvas 6 and 9 Oz, Canvas 2×3×2, PVC coating 25M

0 out of 5﷼26.45 – ﷼1,610.00 -

AVIATION 10″ SNIP MIDWEST USA

5.00 out of 5﷼97.75

Mohammed bin Salman –

Exceptional vibration and seismic control with a deflection range of 3.5 to 13mm – the Rubber Hanger is a game-changer

Mohammed bin Salman –

Revolutionizing vibration and seismic management, the Rubber Hanger offers unprecedented control, boasting a deflection range spanning from 3.5 to 13mm, setting a new standard in the industry.